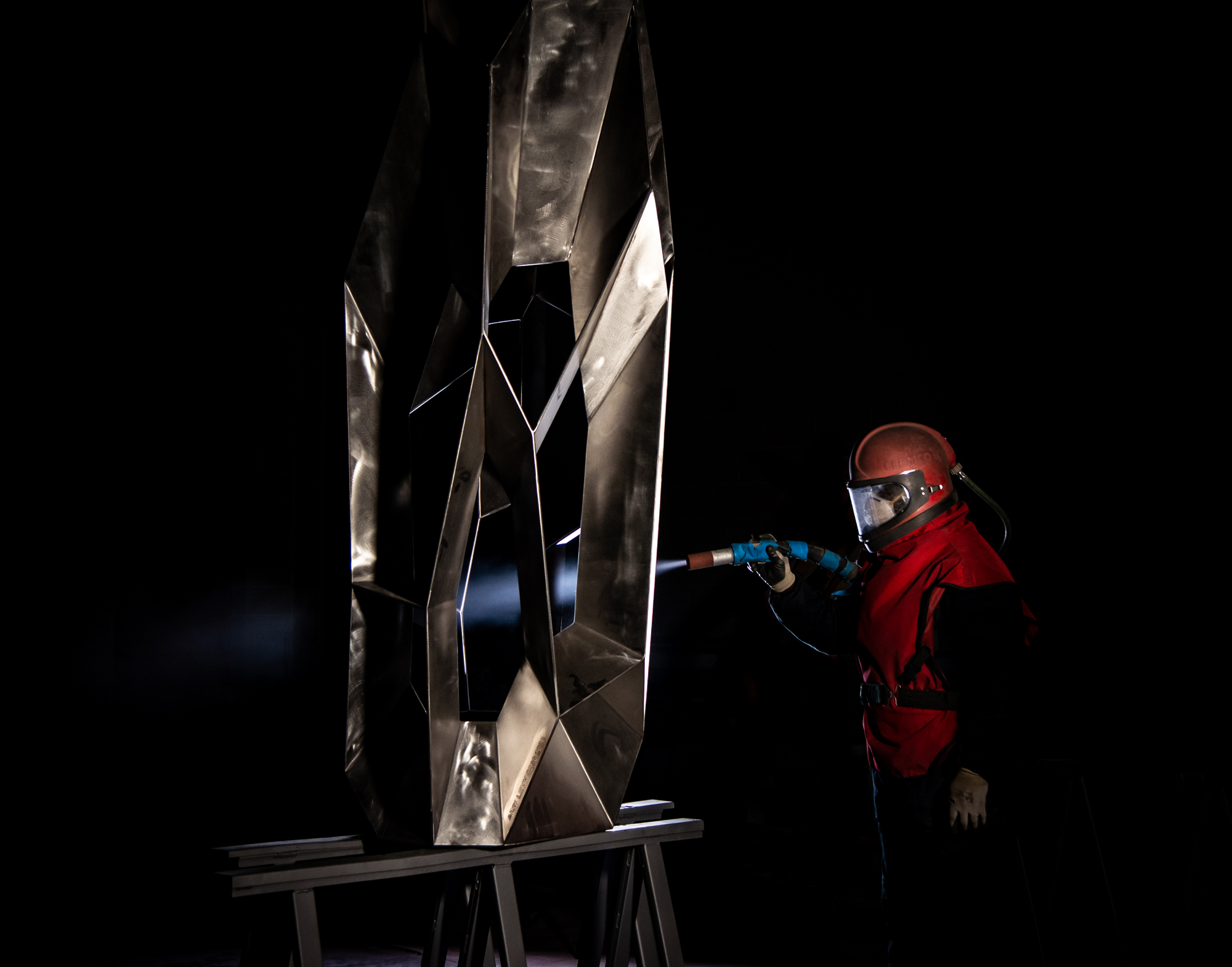

the first step to a great job

Fratelli Folcio with a plant with a capacity of 200 square meters and an overhead crane that carries up to 10 tons is able to manage orders from small to large.

Sandblasting is a cleaning process with which the most superficial layer of a material is removed, through erosion caused by a jet generally composed of sand and air.

It can be performed on a wide range of materials: steel, stainless steel, aluminum, cast iron, wood, ceramics, stone and marble.

Sandblasting objectives: removal of the surface layer, polluted or dirty, of an artifact, preparation of a surface for subsequent painting or the application of a protective treatment.

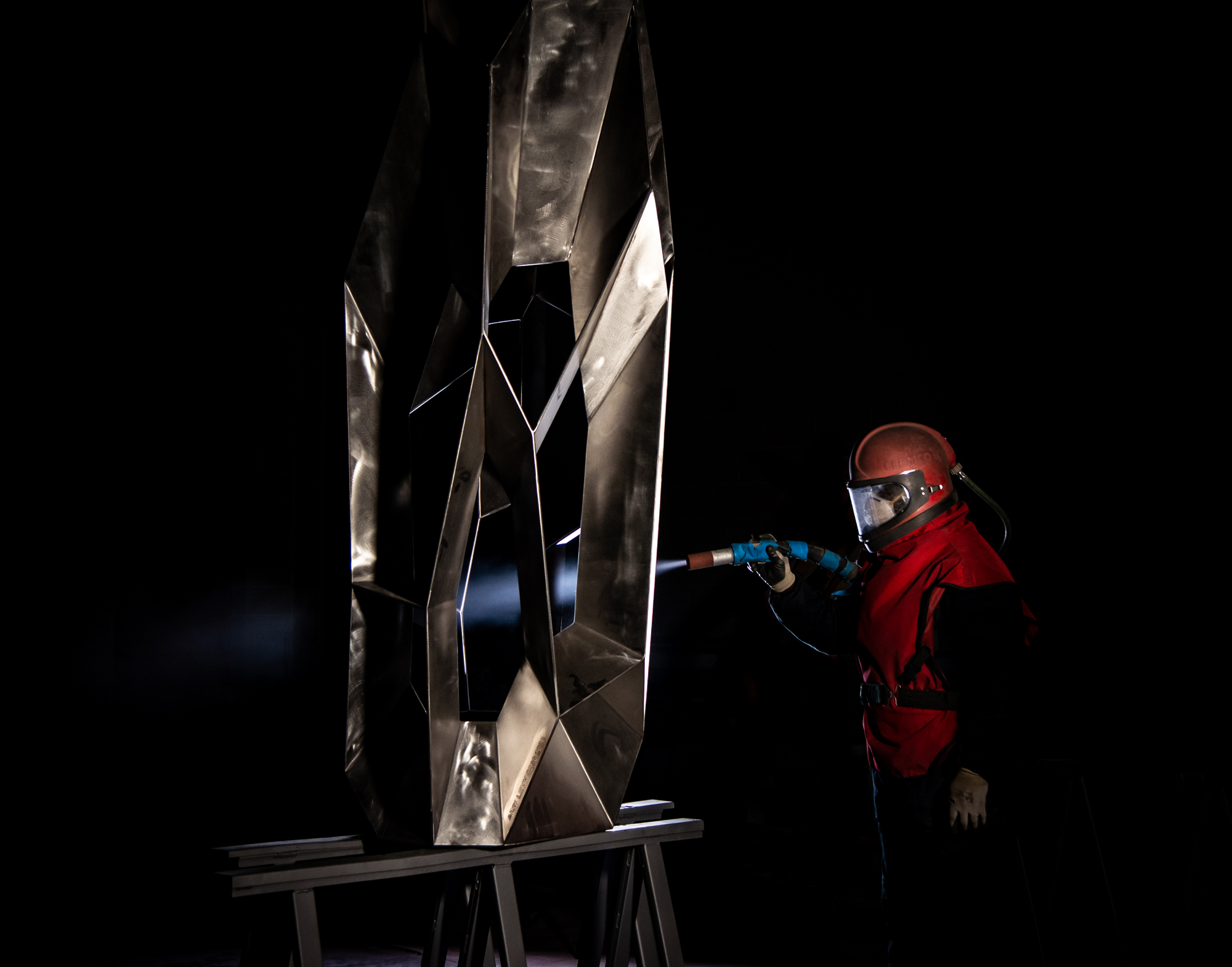

the first step to a great job

Fratelli Folcio with a plant with a capacity of 200 square meters and an overhead crane that carries up to 10 tons is able to manage orders from small to large.

Sandblasting is a cleaning process with which the most superficial layer of a material is removed, through erosion caused by a jet generally composed of sand and air.

It can be performed on a wide range of materials: steel, stainless steel, aluminum, cast iron, wood, ceramics, stone and marble.

Sandblasting objectives: removal of the surface layer, polluted or dirty, of an artifact, preparation of a surface for subsequent painting or the application of a protective treatment.

Each surface layer can be treated with a specific type of sand, the grain size chosen allows a different surface roughness.

Sandblasting is used for the deep cleaning of a surface by removing the surface layer, polluted or dirty, of an artifact.

Depending on the grain size chosen, among the various types of sand used: glass microspheres, steel shot peening, walnut shells, garnet, corundum, different material effects can be obtained.

Fratelli Folcio is equipped with a mobile sandblasting system to carry out sandblasting even on site: construction sites, buildings, wooden ceilings, stone fathers, brick vaults, industrial plants.The quality of the process and the particular attention to detail allow the processing to obtain lasting and refined effects.

Each surface layer can be treated with a specific type of sand, the grain size chosen allows a different surface roughness.

Sandblasting is used for the deep cleaning of a surface by removing the surface layer, polluted or dirty, of an artifact.

Depending on the grain size chosen, among the various types of sand used: glass microspheres, steel shot peening, walnut shells, garnet, corundum, different material effects can be obtained.

Fratelli Folcio is equipped with a mobile sandblasting system to carry out sandblasting even on site: construction sites, buildings, wooden ceilings, stone fathers, brick vaults, industrial plants.The quality of the process and the particular attention to detail allow the processing to obtain lasting and refined effects.

• process on different materials: steel, stainless steel, aluminum, cast iron, wood, ceramics, stone and marble.

• sandblasting on site on artistic monuments

• possibility to intervene on site (wooden ceilings etc …)

F.LLI FOLCIO DI FOLCIO LUIGI & C. SNC

VIA VITTORIO VENETO, 29

22044 INVERIGO (CO) ITALY

031 60 82 50

E-Mail :info@fllifolcio.it

PEC: fllifolcio@pcert.it

© 2021 Fratelli Folcio Snc

PIVA/CF IT 00020010138

Credits

Website: Studio Frog

Photography: Giacomo Albo

Video: Gramvideo